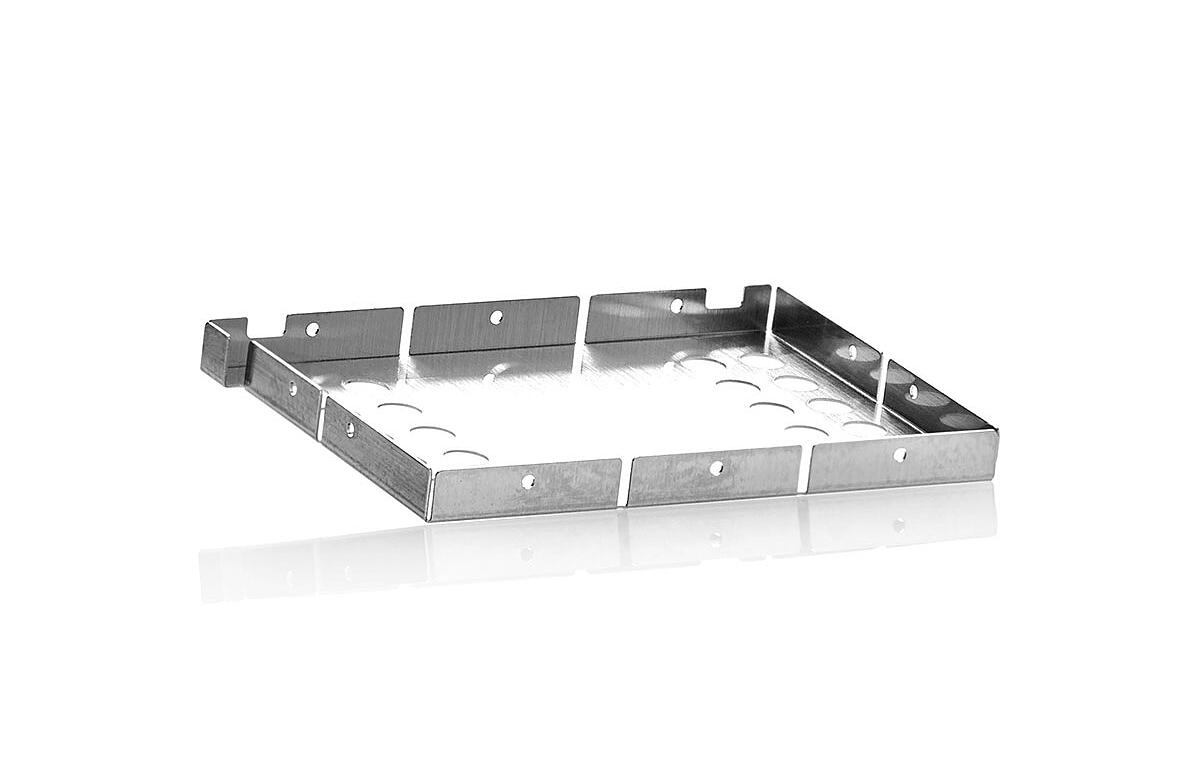

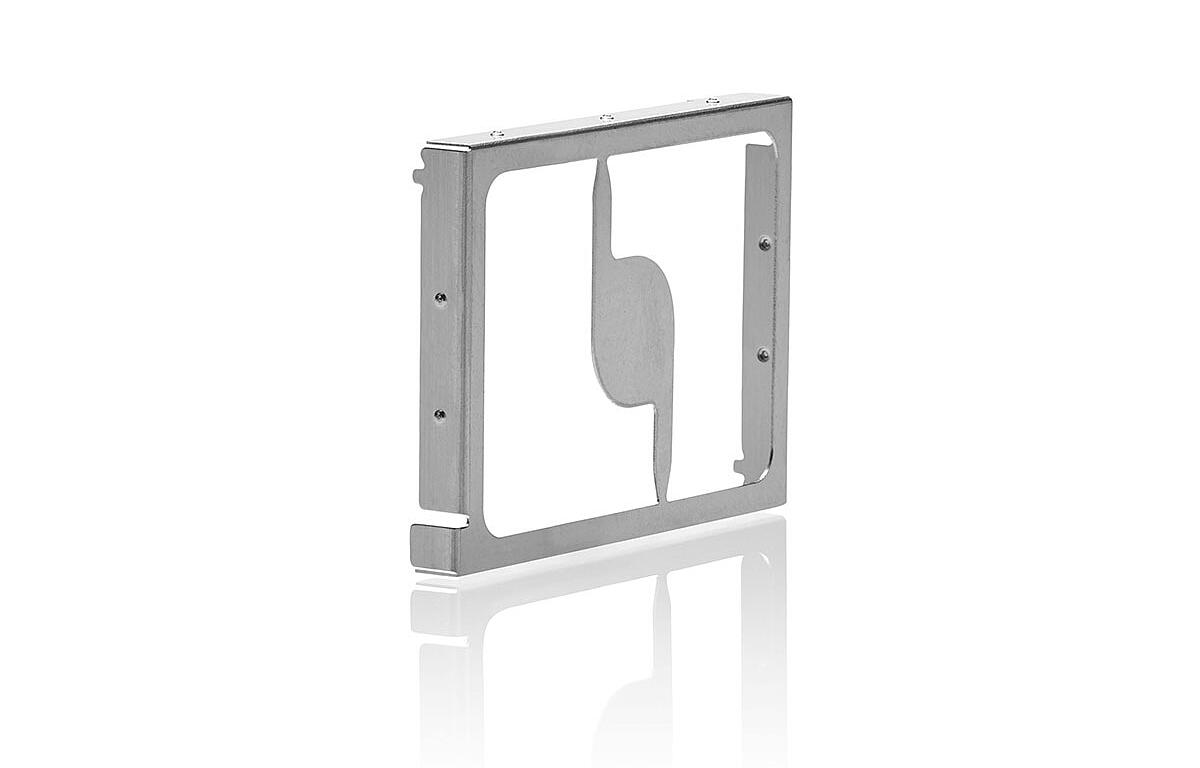

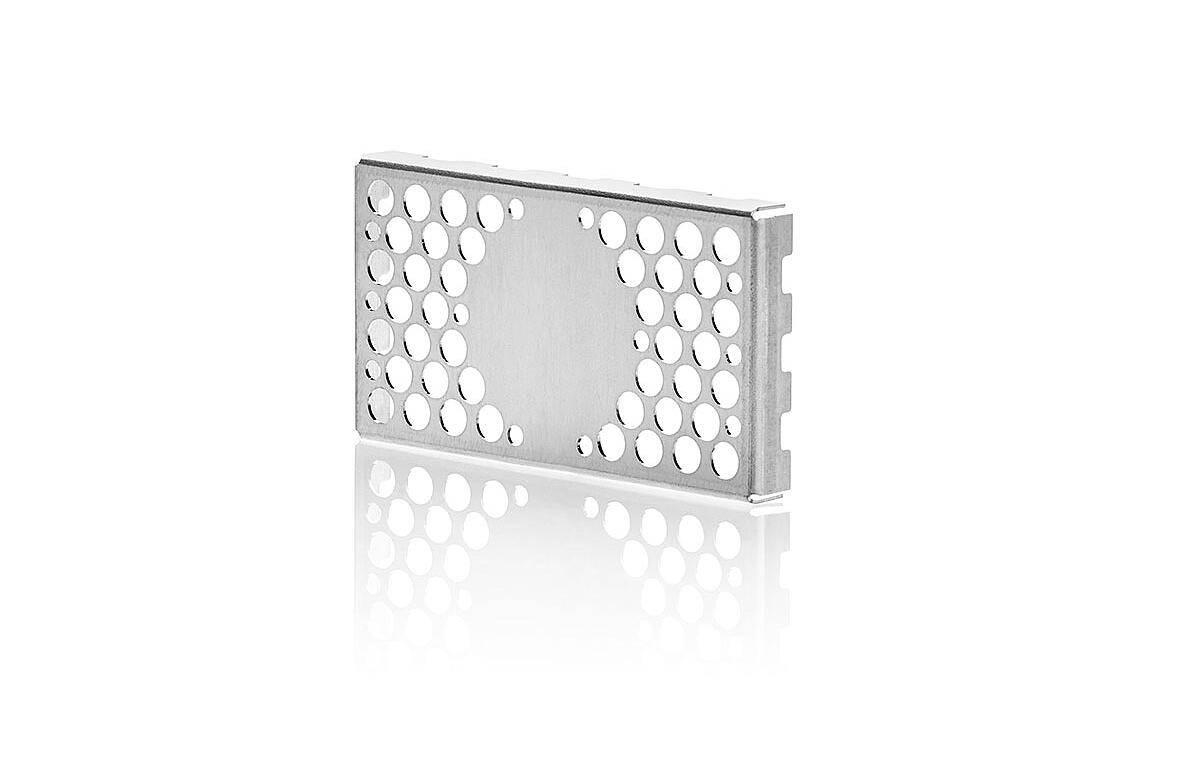

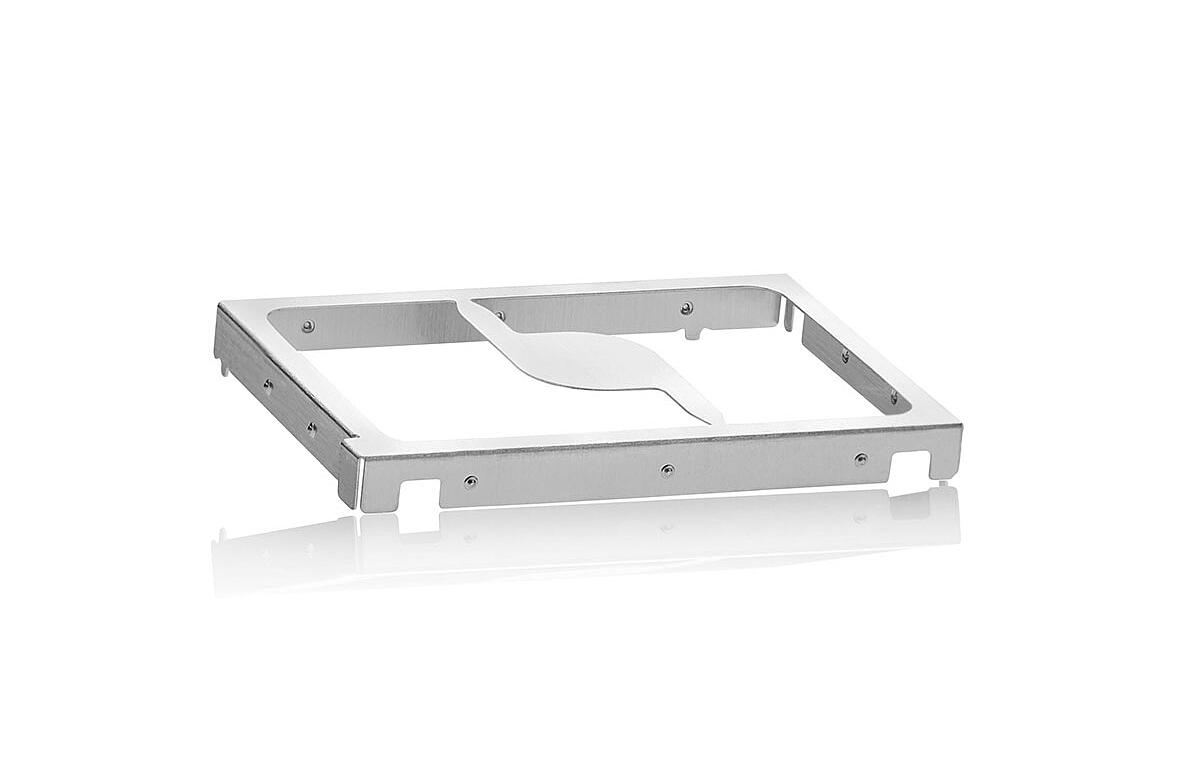

EMI shielding covers serve to shield the electronic equipment from electromagnetic radiation or eliminate them as a source.

We produce and refine them customized to fit perfect with your application.

The typical materials are “white copper, stainless steel or SPTE”, whereby the latter already being pre-tinned in the production process.

Thanks to our very flexible manufacturing processes coupled with our modern stamping and CNC machinery, we are able to produce the shielding plates for you in various widths and material thicknesses.

For a detailed offer, please send us your drawing / 3D data / dimensions together with the requested quantity. We would be happy to provide you with our technical support in order to optimize, both, mechanical and technical, the shielding plate, to your application.

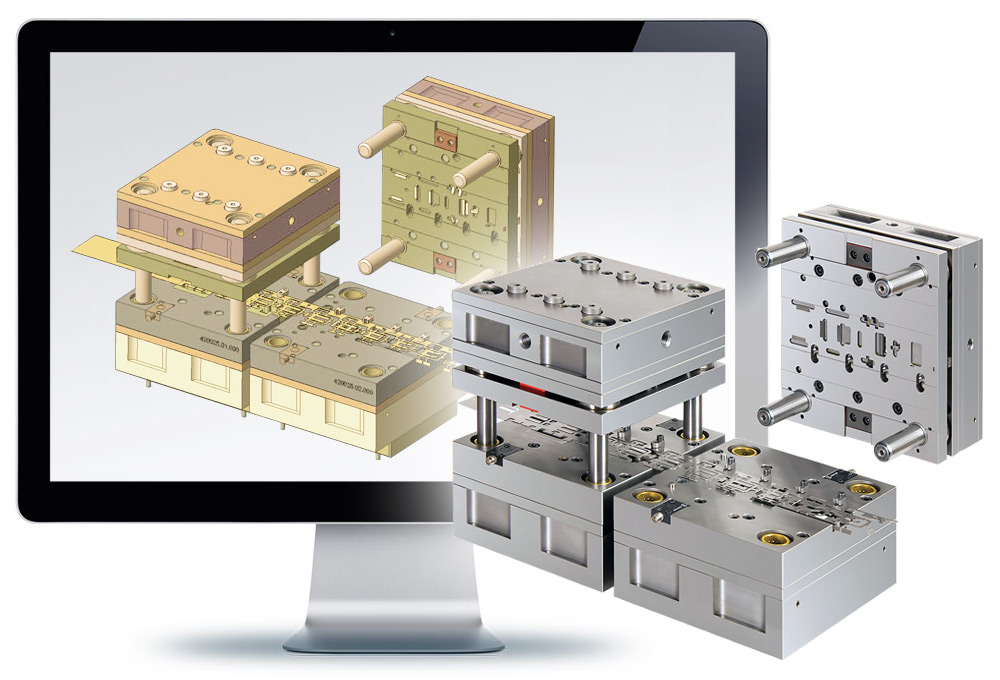

Development and Tool Manufacturing

The solution of customer-specific requirements with a focus on contact systems is very important in our daily work. Your idea (customer requirement) is in the best hands at MPE-Garry and will be implemented flexibly, easily and promptly. We are working with the latest CAD and simulation tools to design and development high-performance and advanced tools for your parts. Already at the beginning of a development we are focusing on an optimized and most economical series production.

Our most modern tool shop with high-precision machines enables the production of high-quality tool parts, which will be used as assemblies in stamping machines or in precision tools. The complete manufacturing process takes place entirely in-house.

Our modular tool system is patented and makes production processes more efficient. All in all, a large number of well-trained specialists is available for the manufacturing and maintenance of these extremely precise tools. Whether milling (HSC, 5x simultaneously), eroding (wire and countersinking), welding, grinding (profile and surface grinding) or turning - we have everything in-house.

Depending on the requirements of the component, MPE Garry is offering a wide spectrum of materials. Many years of experience in handling different steels, various hard metal types, technical ceramics and PM steels are reflected in the construction of the precision tools. Special surfaces are selected based on many years of experience combined with internal tests.

Prototypes are created together with our customers and will be produced with our own bending machines on basis of high-precision lasered or etched blanks. Out of this the development of the bending process can be done very precisely and quickly.

State of the art PLM software and flexible project management will guide you throughout the entire project and beyond.

Our engineers are always in search of new trends and solutions to make even proven processes safer and better. Interdivisional project teams combine the know-how of the individual departments, and this allows better results to be achieved more quickly.

Interdivisional and practiced knowledge management motivates employees to sustainably document information and experience gained in dealing with everyday issues. This knowledge generates a wide basis for future projects in order to work more efficiently and better.

Production

Especially we would like to point out in our production

- special mounting systems, custom tailored to the products, which are developed and built by ourselves

- this directly results in an optimized manufacturing processes of precision connectors

- special test devices integrated in our production machines ensures the quality of the manufactured products

- a state-of-the-art machine park with the latest Bruderer punching machines up to 40 t and table lengths up to 110 cm

- state-of-the-art camera systems for inline measurement of component features with signal processing and feedback to the punching machines

- a large number of punching and punching bending machines enabling us to produce very high quantities within a very short time in the highest quality level

- a flexible modular design of our stamping tools minimizes the set-up times and increases the flexibility in our production.